Sign up for FlowVella

Sign up with FacebookAlready have an account? Sign in now

By registering you are agreeing to our

Terms of Service

Loading Flow

Initial Testing

Laboratory Process Guide 2023

INITIAL TESTING

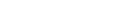

XRF – Analysis of termination finish

Equipment: Fischerscope XRF XDAL

Destructive?: No

Duration: PR9 10 mins – AS6081 30 mins

Description: XRF testing is primarily done to determine the RoHS status although we also confirm the exact termination finish in the process. During testing, an X-Ray beam passes through the component lead and a detector reports what elements that beam hits.

Note; For a device to be determined as RoHS it must contain less than 0.1% Lead (other elements such as Bromine and Mercury are also included in the standard). Anything greater than 0.1% is Non RoHS. As well as this, there are various lead finishes (see glossary) which can usually be confirmed against the Manufacturer’s data.

07