Sign up for FlowVella

Sign up with FacebookAlready have an account? Sign in now

By registering you are agreeing to our

Terms of Service

Loading Flow

Appendix

Laboratory Process Guide 2023

APPENDIX

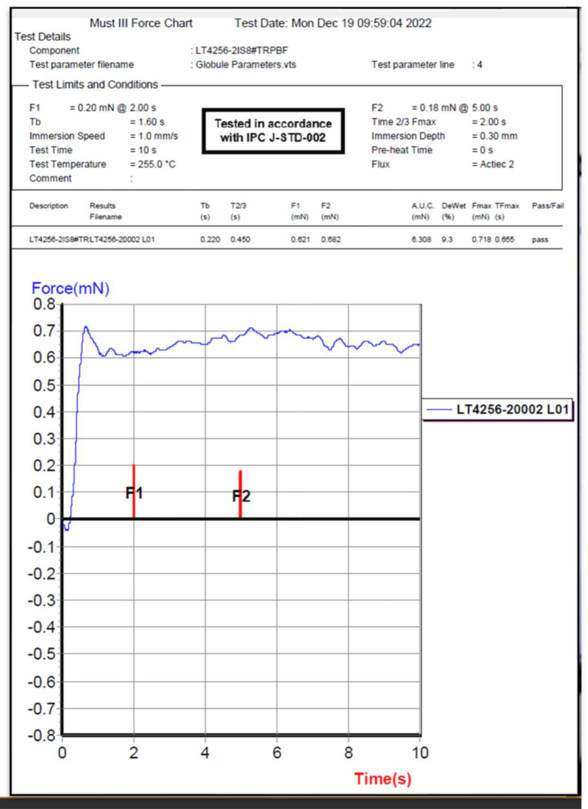

Solderability

Gen3 MUST3

Right; Wetting Balance report – A graph is produced representing the force (in milli-Newtons) required for the termination to ‘wet’. The blue line must climb and continue other the two red parameters (F1 and F2).

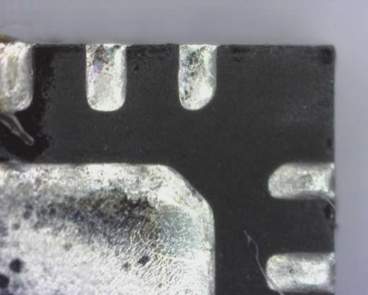

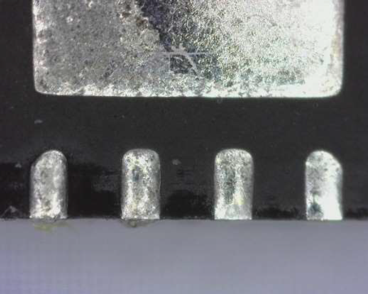

Below; Images taken after a component has been through Dip & Look testing. The Technician is looking at the solder condition and whether there are areas of patchiness and non-adhesion.

21